Mantec’s Porous Ceramic Technology is benefiting the Fertilizer Industry in the efficient production of Nitric Acid.

For many years, Mantec Technical Ceramics Ltd has been a key supplier of Ceramic Filtration Tubes to the Fertilizer Industry. This Case Study explains how the industry has benefited from the use of Mantec’s porous ceramic technology.

Ammonia is used within fertilizers for the production of Ammonium Sulfate, (NH4)2SO4; Ammonium Phosphate, (NH4)3PO4; Ammonium Nitrate, NH4NO3; Urea, (NH2)2CO.

Ammonia Nitrate is produced from gaseous Ammonia and aqueous Nitric Acid in an exothermic reaction. Precise control of the reaction system is critical in order to maintain satisfactory production yields. Any contamination of the catalyst results in a significant downturn in production.

Part of the production of Nitric Acid for use in fertilisers involves the mixing of Ammonia gas with air. This mixed gas is then fed into the NH3 oxidation reactor.

The filtering of the mixed gas is therefore of critical importance as any particulates carried downstream could result in expensive failure of in the reactor.

Before the gas is fed into the reactor, it is passed through the mixed gas filter vessel, into which Mantec’s ceramic filtration tubes are installed. Ceramics are used due to their ability to function in hot and aggressive environments.

Before the gas is fed into the reactor, it is passed through the mixed gas filter vessel, into which Mantec’s ceramic filtration tubes are installed. Ceramics are used due to their ability to function in hot and aggressive environments.

The gas mixture is around 10% Ammonia / 90% air and typical flow rates through such a vessel would be 240 m3/hr at 230°C.

Installation of Mantec’s ceramic filters in the Mixed Gas Vessel These filter vessels typically contain 900 to 1000 filter assemblies.

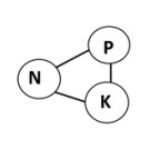

The tube assembly includes a ceramic tube or tubes, a head piece, a blanking plate and a tie rod, usually constructed from stainless steel. (see diagram). The pre-assembled tubes are then suspended through a perforated plate in the top of the vessel.

The successful filtration of the mixed gases through Mantec’s ceramic filters means that they are free from particulates which would otherwise be detrimental to the downstream catalyst. This means that the efficient production is maintained. For more information, please contact Mantec.