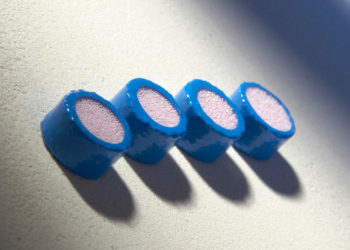

Mantec’s Puremet Metal Pour Filters are unique ceramic filters formed as a reticulated, irregular, three dimensional, open cell structure with a high average surface area. These filters are used extensively in casting aluminium alloys, stainless steel, super alloys, cobalt and copper alloys, zinc and zinc alloys, iron and steel.

The Benefits

By reducing the level of non-metallic inclusions and oxide films that are present in the molten metal, filtering:

- Improves mechanical properties of castings

- Increases process yield

- Reduces porosity in the metal thus improving quality

- Lengthens tool life in post foundry operations

- Gives increased productivity

Filtration benefits all castings and alloy preparation process. A wide range of shapes and sizes are available. Puremet filters are graded by pore size from 30 to 60 PPI (Pores per linear inch).

Structure of the Filter Material

The reticulated, irregular, 3 dimensional open cell network of filaments in the Puremet Filter causes the molten metal to follow a tortuous path through the filter and helps the ceramic material to retain particles much smaller than the pores themselves.

Puremet Filters are specifically designed ceramic compositions with no organic binders. These special formulations remove the risk of aggressive interaction, and the leaching of elements into certain alloys.

Puremet Ceramic Filters for Better Quality Castings

Metal filtration is an essential aid to the production of low-cost, high quality castings. When Mantec’s Puremet Filter is in use:

- The filter is positioned in the runner system, cup or gate so all molten metal passes through before entering the mould cavity

- The filter requires approximately 3 times the cross sectional area of the adjacent runner system to prevent restriction of metal flow.

- The filter reduces turbulence and sand-wash in the metal flow.

Mantec’s Puremet filters are used extensively in casting aluminium, aluminium alloys, stainless steel, super alloys, cobalt and copper alloys, zinc and zinc alloys, iron and steel.

Chemical Composition

Typical composition: 81% Al2O3, 14% SiO2, 2.5% K2O and Na2O (minor oxides TiO2, Fe2O3, MgO, CaO, Cr2O3).